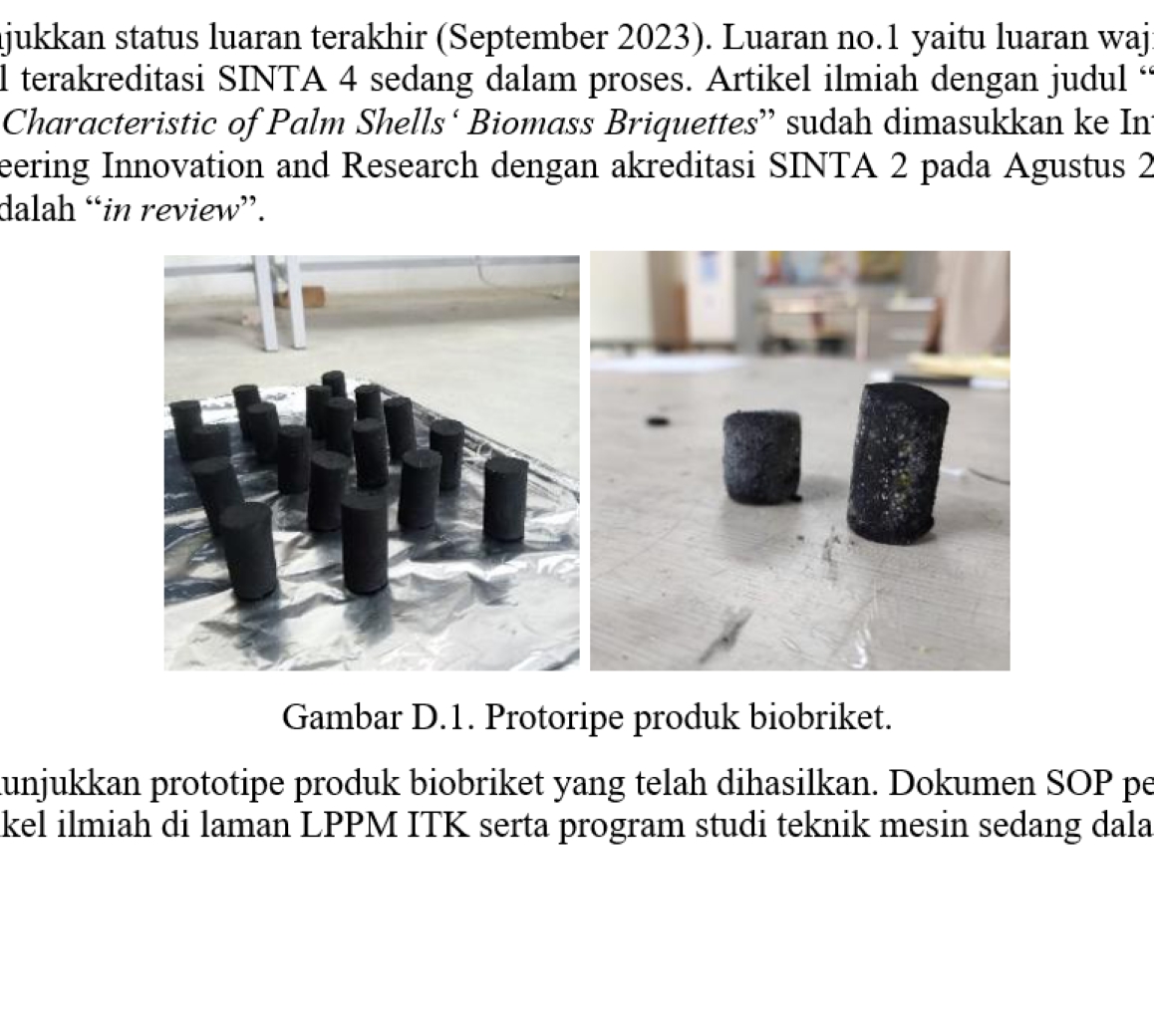

Palm oil shells are an example of a waste product from the palm oil processing industry which can be used as a new renewable alternative energy source in the form of briquettes. The palm oil shells in this study were first carbonized for 1 hour with a heating temperature in a muffle furnace of 600?C, then crushed and smoothed, then kneaded with each variation of adhesive and molded so that the dough could form a cylinder with a diameter of 2 cm and a height of 4 cm. . The average calorific value obtained for cornstarch adhesive, rice flour adhesive and pine resin adhesive was 6634.29 cal/gr, 6702.47 cal/gr, and 7798.31 cal/gr, respectively. The average water content of cornstarch adhesive, rice flour adhesive and pine resin adhesive was 5.1%, 5.0% and 3.7% respectively. The average values ??of volatile substance content in cornstarch, rice flour and pine resin adhesives were 30.90%, 31.70% and 60.73% respectively. The results of this research show that every increase in heating value will be followed by a decrease in water content and varying values ??of volatile matter content. The hope is that the emergence of small-scale prototypes of biobriquettes will encourage further research for implementation in larger scale industries such as the electrical energy industry. As we know, the majority of electrical energy sources in Indonesia still use coal, with the emergence of biobriquettes it is hoped that it can provide a sustainable fuel option for generating electricity in Indonesia.